Unlock the full potential of 3D biology

Pioneering a new future of drug discovery rooted in 3D biology will empower researchers to personalize therapies, reduce a medicine’s time to market, and enhance quality of life for patients around the world.

Molecular Devices has been a life sciences industry leader for 40 years. We believe in the revolutionary promise of 3D cell models to advance next generation drug discovery. Whether you’re making the transition from 2D to 3D cell culture for the first time, scaling your organoid development program, or integrating a fully-automated screening workflow, we’re here to help.

Our robust portfolio of end-to-end high-throughput solutions, user-friendly AI-powered data analysis, and committed 3D biotechnology investments, will support you in overcoming all your 3D biology challenges, starting with:

*NEW* CellXpress.ai® Automated Cell Culture System

An AI-driven cell culture innovation hub that automates processes, improves workflows, and makes assays more reliable and reproducible with machine learning-assisted monitoring, feeding, imaging and scheduling.

3D Ready™ Organoid Expansion Service

Quality-controlled organoids are manufactured at scale, leveraging proprietary bioreactor and bioprocess technology to produce reliable and predictive PDOs.

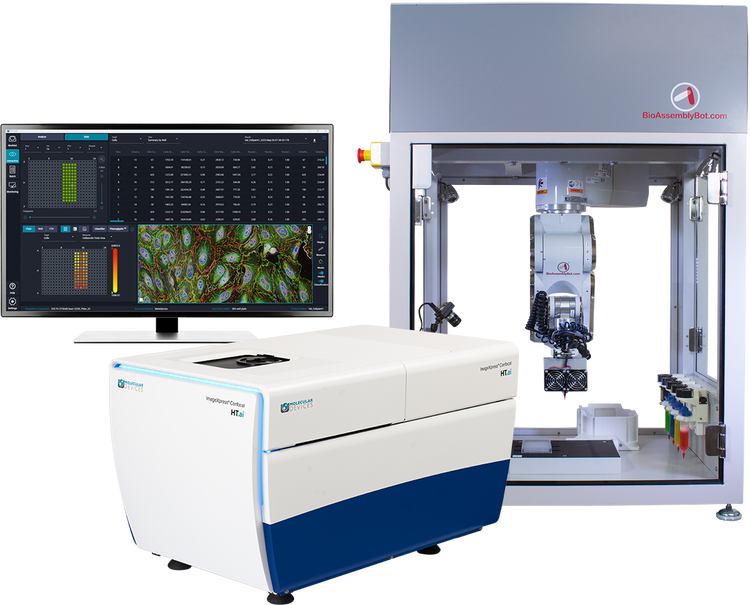

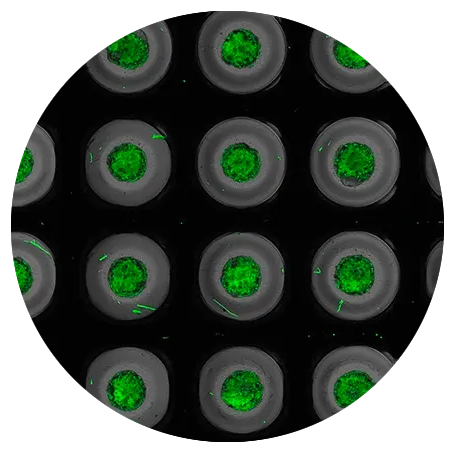

Automated 3D Bioprinting Platform for High-content Screening

Scale in-house organoid and 3D tissue development with an automated bioprinter, high content imager, and AI-powered analysis software.

https://share.vidyard.com/watch/zbx5hvfDZWnGzvrWpoM9id

Dr. Oksana Sirenko, Sr. Scientist, explains how 3D cell models and high-content imaging are helping to advance Drug Discovery

Comprehensive solutions for an fully-integrated, end-to-end automated high-throughput screening workflow

Don’t walk your 3D Biology journey alone. Our specialized team of automation engineers and PhD-level scientists offer services from consultation to implementation. We take time to understand your application process and biological requirements to customize a solution that fits your research needs — one that delivers reproducible results, by verifying optimal performance in-house prior to installation in your lab — helping safeguard your investment with proof of concept and validation services.

3D Biology: The paradigm shift in next-generation drug discovery [interactive infographic]

The revolutionary promise of 3D Biology

We believe organoids are the future of next-gen drug discovery, offering revolutionary promises to reduce drug development timelines, overcome limitations of conventional cell models, and move us away from animal research.

Are you ready to transition from 2D to 3D biology, but not sure where to start? In our latest blog, we show you what it takes to enter into this new drug discovery paradigm.

Introducing the *NEW* CellXpress.ai® Automated Cell Culture System

An AI-driven cell culture innovation hub that automates processes, improves workflow, and makes assays more reliable and reproducible with machine learning-assisted monitoring, feeding, imaging, and scheduling.

It’s a revolutionary system that gives your team total control over demanding feeding and passaging schedules—reducing hands-on time in the lab while maintaining a 24/7 schedule for growing and scaling multiple PDO/iPSC cell lines, spheroids, or organoids.

With the CellXpress.ai cell culture system, you get both an advanced instrumentation solution that’s built to reliably manage the entire cell journey, and powerful, integrated software designed to help you navigate and monitor even the most complex cell culture workflows—including built-in protocols for generating organoids.

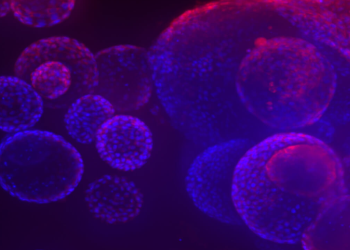

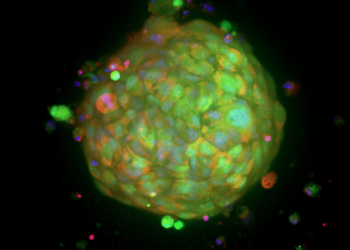

3D Ready™ Organoid Expansion Service

Quality-controlled organoids are manufactured at scale, leveraging proprietary bioreactor and bioprocess technology to produce reliable and predictive PDOs.

Molecular Devices has global leadership in the scale-up and industrial manufacture of human-derived 3D organoids. Facilitated by our unique, patent-pending bioprocess technology, our semi-automated procedure uses controlled, monitored conditions to produce large numbers of standardized patient-derived organoids (PDOs) within a defined size range. Rigorous quality control ensures reduced batch-to-batch and user-to-user variability.

We offer the capability to scale up your proprietary organoid lines to meet your specific requirements.

Automated 3D bioprinting platform for high-content screening

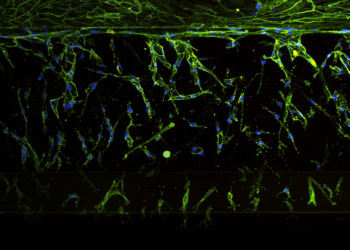

Turnkey platform integrates flexible robotic automation with high-content imaging of complex 3D cellular models, enabling high-volume organoid screening

BAB 400 for drug discovery includes specific enhancements to Advanced Solutions’ existing bioprinting platform that helps life scientists overcome the challenges of reproducing consistent, complex organoid models at scale for drug development.

Out-of-the-box integration of the BAB400 with our ImageXpress®Confocal HT.ai system and IN Carta machine-learning analysis software enables turnkey automation of cell health monitoring and end-point assays.

Organoid Innovation Center

Streamline end-to-end workflows with next-generation 3D biology technologies, customized into a fully-integrated, automated setup for any lab.

The Organoid Innovation Center at Molecular Devices showcases cutting-edge technologies with novel 3D biology methods to address key challenges of scaling complex 3D cell-based assays. The collaborative space brings customers and researchers into the lab to test automated workflows for organoid culturing and screening, with guidance from in-house scientists.

Molecular Devices adds proprietary patient-derived organoid technology with acquisition of Cellesce

Molecular Devices expands global R&D hub in Austria

Molecular Devices and HeartBeat.bio announce collaboration to automate and scale cardiac organoids for high-throughput screening in drug discovery

Molecular Devices continues investment in Organoid Innovation Center adding cell engineering capabilities to automated 3D cell culture platform

Molecular Devices opens Organoid Innovation Center

Featured Research & Applications

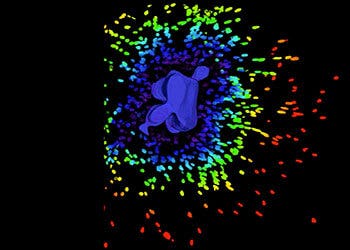

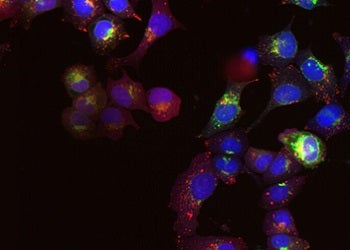

3D Cell Models

Development of more complex, biologically relevant, and predictive cell-based assays for compound..

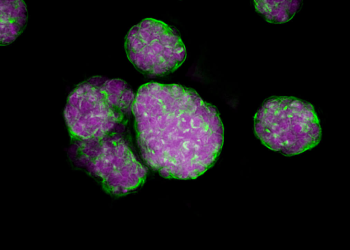

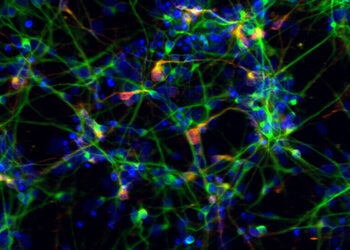

Organoids

Organoids are three-dimensional (3D) multi-cellular, microtissues derived from stem cells that..

Organ-on-a-chip

Organ-on-a-chip (OoC) is a technology that uses microfabrication techniques to create..

Patient-derived organoids (Tumoroids)

The use of patient-derived tumor tissue has transformed the field of drug and target..

Cancer Research Solutions

Cancer involves changes which enable cells to grow and divide without respect to normal limits, to...

Stem Cell Research

Stem cells provide researchers with new opportunities to study targets and pathways that are more...

Drug Discovery and Development

The drug discovery landscape is shifting, with more scientists centering cell line development..

Cell Line Development

Stable cell lines are widely used in a number of important applications including biologics (e.g....