3D Ready Organoid Expansion Service

Advanced Organoid Production: Streamlined, Scalable, and Quality-Controlled

Patented Bioprocess Technology for Scalable Organoid Production

The 3D Ready™ Organoid Expansion Service provides researchers with large numbers of high quality, low-variability organoids in a convenient assay-ready format.

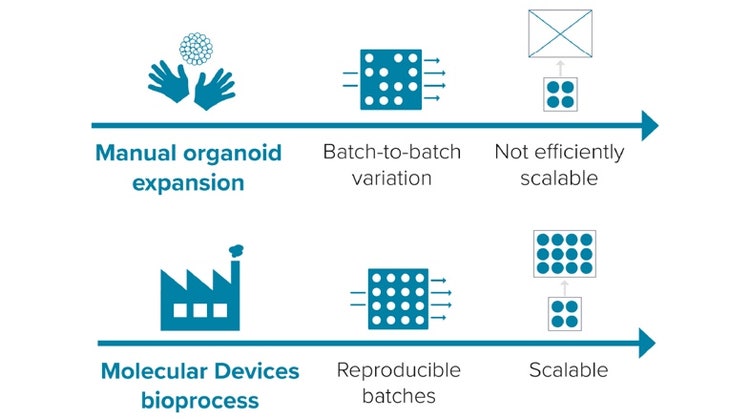

We understand the challenges posed by traditional manual organoid culturing which results in low numbers of inconsistent, non-reproducible organoid batches. Our expertise and patented bioprocess technology revolutionises the field by providing batches of many millions of reproducible organoids. With our 3D Ready Organoid Expansion Services, you can now generate data from repeat assays or high-throughput screens with enhanced statistical relevance and reliability.

Custom Organoid Expansion: Scale up Your Research with Confidence

Our unique and customized service in organoid expansion allows you to expand your own organoid lines to a scale that perfectly aligns with your research requirements. With the capability to generate many millions of organoids, you can now conduct screens involving large numbers of organoids, enabling robust statistical analysis. Our commitment to delivering consistent and reproducible organoid batches ensures reliable data, empowering you to confidently screen thousands of compounds while maintaining the integrity of your research.

Reproducible Organoids: Unrivaled Quality and Standardization

Leveraging our advanced industrial bioprocess, we produce large quantities of organoids with unparalleled quality. Each batch undergoes a rigorous quality assurance process, adhering to our stringent standards. We guarantee uniformity within and between batches, ensuring reproducibility and standardization. If needed, we also provide customizable quality control options to meet your specific requirements, giving you complete control over the quality of your organoids.

Assay-Ready Organoids: Streamlined Workflow, Accelerated Research

Say goodbye to the hassle of organoid culture with assay-ready organoids expanded from your own organoid lines. These ready-to-use consumables can be conveniently stored in your lab's freezer until you need them. By eliminating the time-consuming task of organoid culture, you can optimize your lab efficiency and dedicate more time to your research. Our solution streamlines your workflow, empowering you to focus on your scientific investigations and accelerate your discoveries.

Features

Assay-Ready Convenience

Our organoids are conveniently available in frozen vials, ready for immediate use whenever you need them.

Scalable Production

With the ability to produce over 10 million reproducible organoids, our process empowers high-throughput and repeat assays, facilitating efficient and robust experimentation.

Reproducible Models

By minimizing variability and delivering consistent batch-to-batch results, our organoids enhance the quality of your data, enabling you to achieve reliable and reproducible research outcomes.

Outsourced Expertise

Save time and resources by entrusting your organoid production to our team of experts, who deliver high-quality results while freeing up your valuable in-house resources.

Stringent Quality Control

Our rigorous and customizable quality control process ensures that our organoids consistently meet the highest standards, providing accurate and reliable data for your research.

Customized Solutions

Tailored to your specific requirements, our customized expansion projects allow you to scale up your own organoid lines and maintain the integrity of your unique research goals.

From Vision to Reality: A Tailored Organoid Expansion Experience

We collaborate closely with you to gain a comprehensive understanding of your unique requirements. Our aim is to facilitate the successful expansion of your own organoid lines, tailored to meet your specific needs and goals.

We have a proven track record of supporting pharmaceutical corporations, biotechnology companies, and academic institutions by expanding their organoid lines. Our expertise lies in providing high-quality, standardized organoids that meet the rigorous demands of the life science industry.

- Project Scoping: Our experts engage in in-depth discussions with you to understand your project requirements, including suitability, scale, quality control, and timelines. We tailor the process to meet your specific needs.

- Pre-Expansion: We determine the parameters specific to your organoid line within the bioreactor, ensuring optimal conditions for expansion.

- Bioreactor-Based Expansion: Using our bespoke bioreactor system, we expand the organoids. The harvested organoids are carefully counted, sized, and cryopreserved in vials for future use.

- Quality Control Testing: Thawed vials undergo rigorous quality control testing. This includes assessing post-thaw recovery, pathogen testing and other custom quality control measures such as drug validation and STR analysis.

- Reproducible Batches: Each batch can contain over 10 million organoids, ready to be thawed, plated, and tested according to your needs. This ensures consistent and reliable access to organoids for your research.

Latest Resources

Featured Applications

Customer Breakthrough

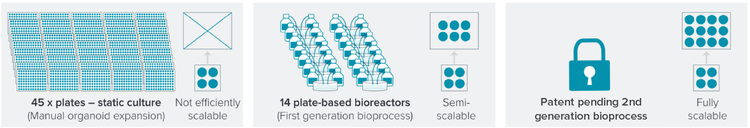

Organoid expansion process – efficient, reproducible, scalable

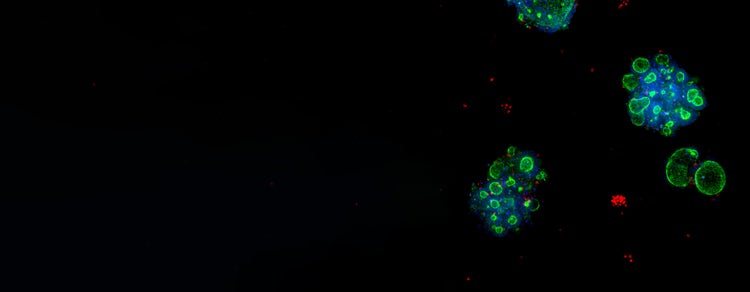

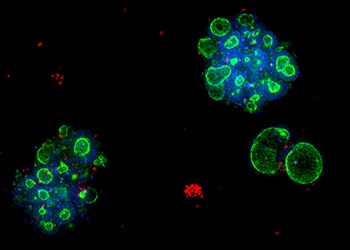

Quality-controlled organoids are manufactured at scale for high-throughput screening, leveraging proprietary bioreactor and patent-pending bioprocess technology to produce efficient, reproducible, scalable PDOs. These can be deployed in many applications, including drug discovery and organ-on-a-chip applications.

Until recently, organoids could only be grown and expanded manually. This is a technically challenging, time-consuming, and labor-intensive process resulting in small numbers of inconsistently sized organoids, limiting their suitability for use in high throughput applications and widespread use by big pharma and biotech.

This 'disruptive’ Molecular Devices bioprocess, now in its second generation, has enabled a significant increase in standardized PDO volume production compared to manual processes. Improved process control, including the use of inline sensors and real-time monitoring, ensures precise culture conditions for large, reproducible batches of standardized organoids. This is a significant step change from existing manual PDO culture methods, enabling organoids to be used in high-throughput assays earlier in the drug discovery cascade.