How are monoclonal antibodies produced?

The traditional monoclonal antibody (mAb) production process usually starts with generation of mAb-producing cells (i.e. hybridomas) by fusing myeloma cells with desired antibody-producing splenocytes (e.g. B cells). These B cells are typically sourced from animals, usually mice. After cell fusion, large numbers of clones are screened and selected on the basis of antigen specificity and immunoglobulin class. Once candidate hybridoma cell lines are identified, each "hit" is confirmed, validated, and characterized using a variety of downstream functional assays. Upon completion, the clones are scaled up where additional downstream bioprocesses occur.

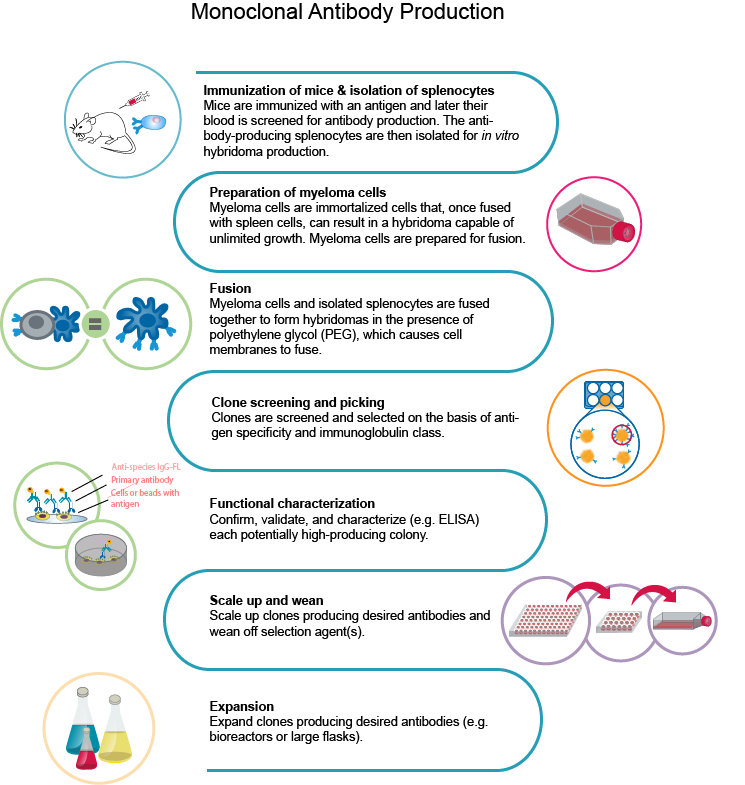

A typical monoclonal antibody production process.

- Immunization of mice & isolation of splenocytes - Mice are immunized with an antigen and later their blood is screened for antibody production. The antibody-producing splenocytes are then isolated for in vitro hybridoma production.

- Preparation of myeloma cells - Myeloma cells are immortalized cells that, once fused with spleen cells, can result in hybridoma capable of unlimited growth. Myeloma cells are prepared for fusion.

- Fusion - Myeloma cells and isolated splenocytes are fused together to form hybridomas in the presence of polyehthylene glycol(PEG), which causes cell membranes to fuse.

- Clone screening and picking - clones are screened and selected on the basis of antigen specificity and immunoglobulin class.

- Functional characterization - Confirm, validate and characterize (e.g. ELISA) each potentially high-producing colony

- Scale up and wean - Scale up clones producing desired antibodies and wean off selection agent(s)

- Expansion - Expand clones producing desired antibodies (e.g. bioreactors or large flasks).

A typical monoclonal antibody production process.

Monoclonal vs polyclonal antibody production

Understanding monoclonal vs polyclonal antibody production reveals distinct methods in the field of biotechnology and pharmaceutical research for creating antibodies. Monoclonal antibody production involves a detailed process that begins with the creation of hybridomas, leading to the generation of specific antibodies. This method contrasts with polyclonal antibody production, where animals such as rabbits or goats are immunized to produce antibodies that are purified from the serum. Monoclonal techniques emphasize specificity and reproducibility through the selection and scaling of particular B-cell clones. In contrast, polyclonal methods offer rapid production and cost efficiency, albeit producing a variety of antibodies with different specificities. This introduction compares the development, benefits, and uses of these critical biotechnological tools in therapeutic and diagnostic applications.

Workflow solution for mAb production

Developing monoclonal antibodies represents a pivotal advancement in biomedical science, offering targeted treatments for a range of diseases, including cancer, autoimmune disorders, and infectious diseases. This process involves the creation of antibodies that are identical and derived from a single cell lineage, ensuring high specificity and efficacy in therapeutic applications.

mAb production utilizes cutting-edge technologies and methodologies to design antibodies that can precisely target and neutralize disease-causing agents. With its critical role in the development of targeted therapies, mAb production enhances the effectiveness of treatments, minimizing side effects compared to traditional approaches. Its importance in medical research and patient care continues to grow, reflecting its role in advancing health outcomes and personalized medicine.

Related mAb application and resources

Explore our resources to see how our advanced technologies simplify the monoclonal antibody development process. Learn about the benefits of streamlined workflows and accurate monoclonality assurance, and how they can revolutionize your research.

Workflow process for monoclonal antibody production

Explore the precision-driven process of producing monoclonal antibodies, from immunization to scalable clone expansion.

Workflow solution for mAb production

Immunization and Splenocyte Isolation

In the monoclonal antibody production process, mice are immunized with antigens, and their antibody-producing splenocytes are isolated for in vitro hybridoma production.

Myeloma Cell Preparation

Myeloma cells are immortalized cells that, once fused with spleen cells, can result in hybridoma capable of unlimited growth. Myeloma cells are prepared for fusion.

Fusion for Hybridoma Formation

The fusion of myeloma cells with isolated splenocytes, using polyethylene glycol (PEG), is a key step in forming hybridomas, advancing the monoclonal antibody production process.

Mammalian Colony Picker with Monoclonality Assurance

Our enhanced ClonePix 2 colony picker with high-resolution single-cell imaging capability on day zero, can identify and select high-producing, monoclonal clones in one seamless step, merging high-throughput screening with monoclonality assurance for unparalleled efficiency.

Clone Screening and Selection

Clones are meticulously screened and selected based on their antigen specificity and immunoglobulin class to ensure only the most promising candidates move forward.

Functional Characterization of Clones

This step involves the rigorous confirmation, validation, and characterization of each clone, utilizing techniques such as ELISA to identify those with the highest production potential.

Microplate Reader and Cell Imaging System

Facilitating an automated and precise assessment of clone viability and productivity is crucial for advancing the most effective antibodies to the next stage.

https://vids.moleculardevices.com/watch/xgTqMVm4uWCZ4sfkPxycyE

CellXpress.ai Automated Cell Culture System

Significantly enhances both the scale-up and expansion phases by automating the growth of high-yield clones, ensuring a seamless transition from laboratory-scale to large-scale production without compromising quality or specificity.

Scale-Up and Wean

Once clones are deemed suitable, they undergo a scale-up process to increase antibody production, followed by a weaning phase to reduce dependency on selection agents.

Expansion

The production of desired antibodies is further amplified, often in bioreactors or large flasks, to meet the demand for therapeutic applications.

Automate your workflow

We offer scalable, automation-ready workcells ranging from entry-level to advanced, and can be customized to meet your specific research needs

Check out our custom solutions