An automation journey for a high-throughput ELISA workflow

As your lab’s needs expand, automating every step of an intricate workflow provides exponential value. From increased walk-away time and throughput to reduced human error and improved lab safety, automation can keep routine work on track so that scientists can focus on more critical assay development challenges.

An enzyme-linked immunosorbent assay (ELISA) is one of the most popular methods for quantitation of target antigens, but it is also a time-consuming and labor-intensive process. Automating an ELISA workflow can take the tedious steps of sample prep, reagent pipetting, and microplate washing out of your hands and can improve the reproducibility of your results.

Here we discuss key considerations for developing an integrated automated, high-throughput ELISA workcell. No matter where you are in your lab automation journey, these considerations are key to advancing your ELISA workflow solution.

How to develop an automated ELISA system

1. Start with a simple, automated plate handling system

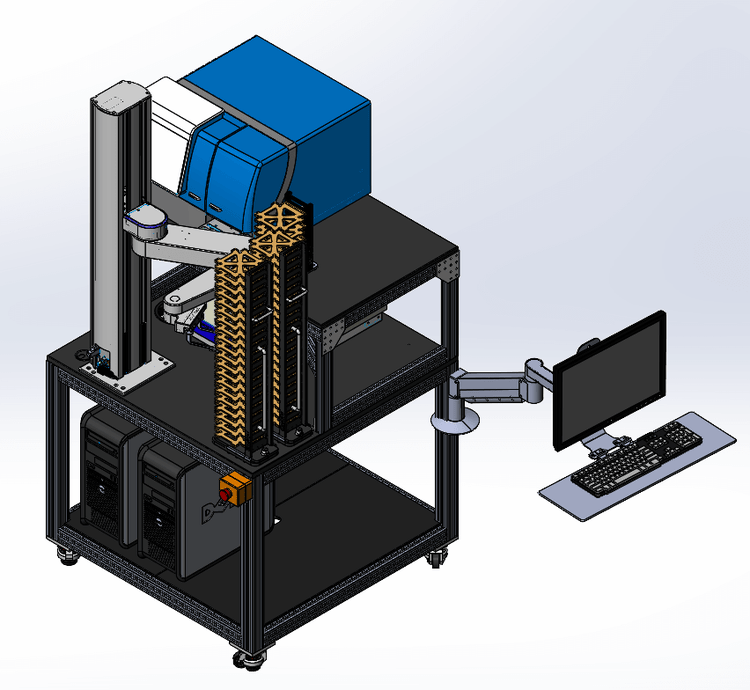

Increase walk-away time by automating plate loading tasks with a sophisticated robotic arm, freeing you up to perform other tasks. This first step in automation can help perform large-scale, plate-based assays efficiently by delivering microplates between an ambient hotel and a microplate washer and reader. The microplate washer automatically washes all wells of the assay plate, using the desired wash program to completely remove unbound reagents and eliminate background noise. The microplate reader then generates data following a preconfigured protocol that performs the necessary calculations on the data, delivering consistent results.

Here you can see the benefits of automating the manual task of plate loading at various steps of the workflow, especially at a large scale. After coating the plate and adding your samples, an integrated control software schedules an automated robotic arm to transfer plates from the ambient hotel to the microplate washer and back to the hotel. The process repeats after you add your reagents once again freeing you from manually loading and waiting for each plate to wash. Finally, you can add your substrates and let the robot feed the plates to the microplate reader and back to the hotel.

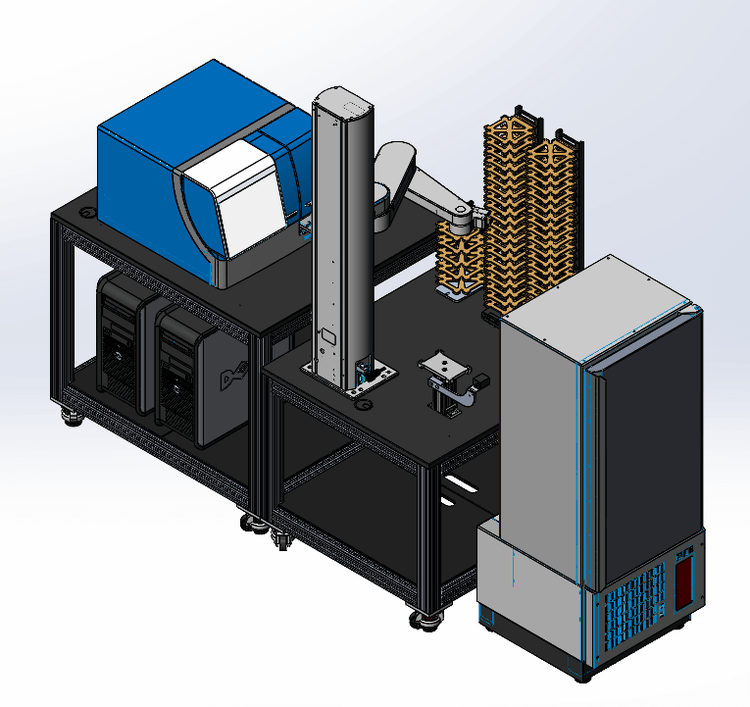

2. Add an automated incubator for cell-based assays

If you are running cell-based assays, you’ll also want to add an automation-friendly incubator that keeps your cells happy at 37°C with 5% CO2. This further increases your efficiency and walk-away time by removing that trek from instruments to incubator and back.

3. Add an automated liquid handling system to remove manual preparing and pipetting

As you continue your lab automation journey, the addition of an automated liquid handling system completely removes the burden of manually preparing and pipetting samples and assay reagents. The illustration below shows how automated liquid handling now replaces steps 2, 4, and 6 of human intervention, converting a labor-intensive ELISA into a truly walk-away workflow.

The robotic arm can be scheduled to deliver plates to and from the liquid handler, incubator, microplate washer, and reader of your automation setup in a method-specific way, completely freeing you from the lab bench. And, as your lab’s needs evolve, your workcell can be integrated with other instruments, like a plate sealer, seal remover, and plate shaker to further optimize your assay process.

4. Consider an automation-ready ELISA workcell

Here we demonstrate five workcells for an integrated solution that combines hardware and software for ELISA-based experiments, offering automation capabilities ranging from entry-level to advanced. No matter where you are at in your automation journey, these workflows can be tailored to your specific research needs according to sample size or sensitivity, as well as the need for increased throughput, efficiency, and walk-away time.

ELISA Workcell: Single-step instrument plate loader

Our entry-level system is a simple, compact, and user-friendly set-up called the ELISA Workcell. It consists of a SpectraMax® Microplate Reader, Peak Robotics S-LAB Plate Handler with the S-LAB software, and the AquaMax® 4000 Microplate Washer.

ELISA Advanced Workcell: Future-proof automated plate loading

ELISA Advanced EC Workcell: Automated plate loading and incubation

ELISA HTS EC Workcell: Two-step instrument plate loader plus liquid handling

The ELISA HTS EC Workcell offers an automated liquid handler and allows the workcell to perform the manual tasks of sample preparation and reagent additions at designated times.

Components of this workcell include a SpectraMax Microplate Reader, AquaMax 4000 Microplate Washer, and LiCONiC STX44 Automated CO2 Incubator. The key addition to the workcell is the Microlab STARlet Robot Liquid Handler from Hamilton Robotics with integrated plate handling system and scheduling software.

HTS EC Workcell provides a significant advantage, particularly for large numbers of samples, which are subject to errors if handled manually. Besides reducing human errors, an automated liquid handling system will drastically reduce your hands-on time manually pipetting. This will enable you to conduct many assays with great precision and minimal manual intervention.

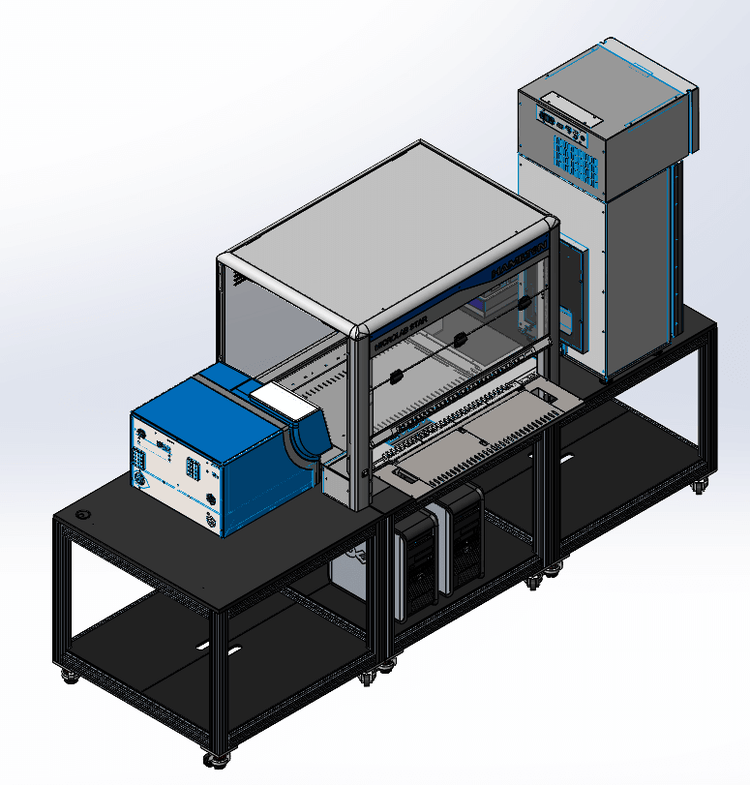

ELISA HTSx Workcell: Fully automated solution

ELISA HTSx WorkCell is the most advanced ELISA workcell in our portfolio, offering a complete, fully automated, walk-away solution. It works with a similar logic to the previous workcell but with a Microlab STAR Automatic Liquid Handler, which offers a much larger sample loading capacity. The system also contains multiple plate hotels, which can store up to 80 microplates.

https://share.vidyard.com/watch/Nyr9umn2JZ2JaeMkQGw3jQ

The solution brings versatility to ELISAs. The STX44 Incubator is optional, depending on your need for non-ambient plate incubation temperatures or cell incubation. With an automated liquid handler, your presence is needed only at the initial loading step. No further manual intervention is required from then on, as the PF400 robot will carry out the transfer between workcell components so that assay steps can be performed at designated times.

Discuss your automated ELISA solution

Automation does not have to be overwhelming – there are a lot of flexibility and options available. Our five ready-made workcells for ELISA workflows offer automation solutions ranging from simple plate-loading capabilities to more advanced, completely automated workcells and the best part, it can be customized and built over time. Automating labor-intensive plate-based assays increases walkaway time, throughput, and reproducibility by reducing a researcher’s need to engage in common, repetitive, hands-on tasks.

Learn more about our ELISA workcells or when you're ready to speak to a workflow automation specialist about your application, contact us.