Application Note

The PathCheck Sensor: a Powerful Tool for Microplate Analyses

- Obtain absorbance values as if you had used a 1 cm cuvette

- Detect pipetting errors

- Correct for volume differences

- Calculate results using extinction coefficients instead of standard curves – DNA, protein, NAD(P)H, etc.

- Validate performance of multichannel liquid handlers

- Extend the dynamic range of your assay to higher absorbances without diluting

- Standardize your results regardless of volume used for assay

Joyce Itatani | Application Scientist | Molecular Devices

Cathy Olsen | Sr. Application Scientist | Molecular Devices

Introduction

The PathCheck Sensor is a revolutionary new awardwinning1 technology in SpectraMax® Instruments for measuring the fluid level in every well of a microplate2–5. By measuring optical pathlength, it eliminates the last major distinction between microplate readers and spectrophotometers. No accessories are needed and SoftMax® Pro Software performs the calculations for you automatically.

The fundamental difference between absorbance measured in a microplate compared to a cuvette is the optical beam configuration. In a cuvette, the optical beam is horizontal and the pathlength through the sample (typically 1 cm) is fixed by the walls of the cuvette. The optical beam in a microplate well is vertical, so the pathlength depends on the volume of fluid and the degree of meniscus formation. Differences in pathlength cause differences in apparent sample absorbance, which makes it confusing to compare results from a microplate and a cuvette. SpectraMax Microplate Spectrophotometers with PathCheck Sensor give the microplate user a new and powerful tool to quickly and easily measure the optical pathlength through every sample in a microplate.

Figure 1. Optical path through a cuvette (left) and a microplate well (right).

Methods

Principle

PathCheck Sensor measures pathlength using the absorbance peak of water in the near infrared (NIR) spectral region. The height of the water’s absorbance peak is proportional to the optical pathlength through the sample (which, in a microplate well, is proportional to the volume of solution.) PathCheck Sensor makes two NIR absorbance measurements at wavelengths not affected by temperature. SoftMax Pro Software software then automatically calculates the pathlength by comparing the peak height in each well to the peak height in a standard 1 cm cuvette. PathCheck is applicable to almost all biological/pharmaceutical molecules in aqueous solution because they have little or no absorbance between 900 nm and 1000 nm at concentrations normally used. PathCheck can also be used with samples containing small amounts of organics or high buffer concentrations by using the Cuvette Reference Method (not explained here.)

Making absorbance measurements normalized to a 1 cm pathlength:

SoftMax Pro Software automatically reports absorbance values normalized to a 1 cm pathlength. The table below shows results obtained with 75 μL to 300 μL yellow reagent.

Optical pathlengths and raw absorbance values were directly proportional to well volumes. After normalization to a 1 cm pathlength, all absorbance values, regardless of the volume in the wells, were within 1% of the value obtained by measuring the same solution in a 1 cm cuvette.

Figure 2. Microplate samples with PathCheck compared to standard 1 cm cuvette.

Extinction-based assays:

Use PathCheck Sensor, enter the extinction coefficient of your compound as a calculation factor, and SoftMax Pro Software will automatically return the concentration in each well. Protein, nucleic acid and NAD(P) H assays can be performed without a standard curve.

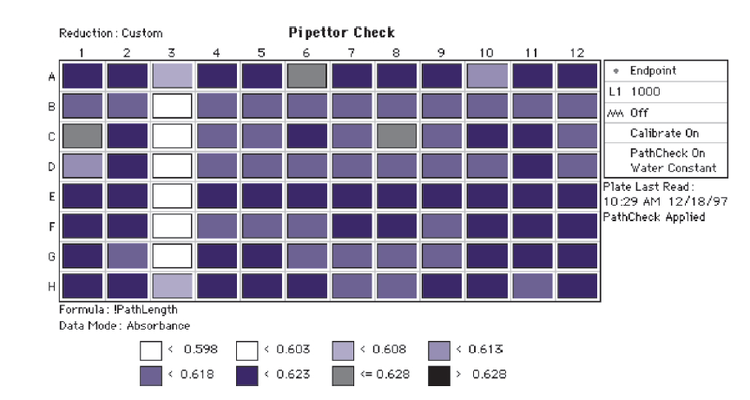

Detect pipetting errors

Easily identify and eliminate sources of error from your data. Read the plate in the SpectraMax instrument using PathCheck Sensor and display the data using grayscale to highlight any irregularities. The example below shows a 12-channel pipettor that was delivering \~2.5 % less volume in one channel (#3.) The wells for that channel have distinctly shorter pathlengths.

Figure 3. Grayscale display of PathCheck corrected data.

Verify performance of multichannel pipettors and dispensers without added dye:

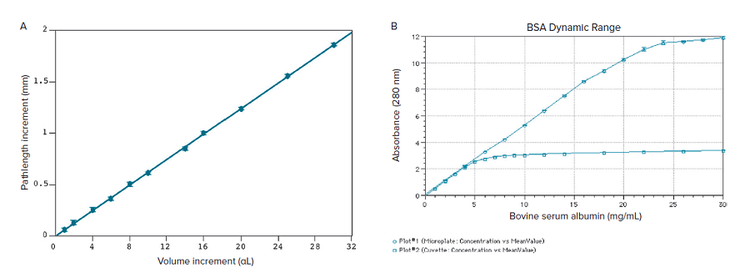

Dispense reagent in replicates into the microplate, then measure pathlength in a SpectraMax instrument using PathCheck Sensor. SoftMax Pro Software will automatically report standard deviations and coefficients of variation for rows, columns, or across an entire plate (for 12 channel, 8 channel, or 96 channel pipettor/dispensers respectively.) SoftMax Pro Software will also calculate the actual dispense volumes from a pathlength /volume standard curve. Dispense volumes can be tested down to as little as 30 μL using the direct method2,5 and as low as 4 μL using the difference method.3,4

Extend assay dynamic range:

Samples can be measured at concentrations up to 4 times higher than in standard cuvettes without diluting. A BSA standard curve read in a 1 cm cuvette deviates from linearity at \~4 mg/mL, compared to \~16 mg/mL in a microplate (pathlength \~0.25 cm).

Figure 4. A) Pathlength/volume standard curve for 1–30 μL dispense volumes. B) BSA measured at 280 nm in a microplate (100 μL/well) with PathCheck Sensor, compared to same samples read in a 1 cm cuvette.

Only PathCheck Sensor:

- Gives temperature-independent pathlength measurements in a microplate reader.

- Can identify pipetting errors in a microplate within seconds.

- Can easily test performance of multichannel pipettors and automated liquid handlers by detecting volume differences.

- Can report results standardized to 1 cm pathlength regardless of the volume actually used.

- Is automated with powerful SoftMax Pro Software software.

References

- Winner of the R&D Magazine top 100 technology products of 1998

- McGown, E.L. and D.G. Hafeman. Anal. Biochemistry 258, 155-157 (1998)

- McGown, E.L. et al. Clinical Chemistry 44(10):2206-8 (1998)

- McGown, E.L. et al. Labor Praxis No. 5:74-75, May 1998

- Anders, A. et al. Labor Praxis No. 10: 78-82, October 1998