Autofocus

Automated focus routines for high-content imaging and analysis

Automated focus algorithms for a variety of applications including custom organ-on-a-chip plates

The ImageXpress Pico system uses two robust autofocus mechanisms:

- Detect Surface – hardware autofocus

- Find Best Plane – image-based autofocus

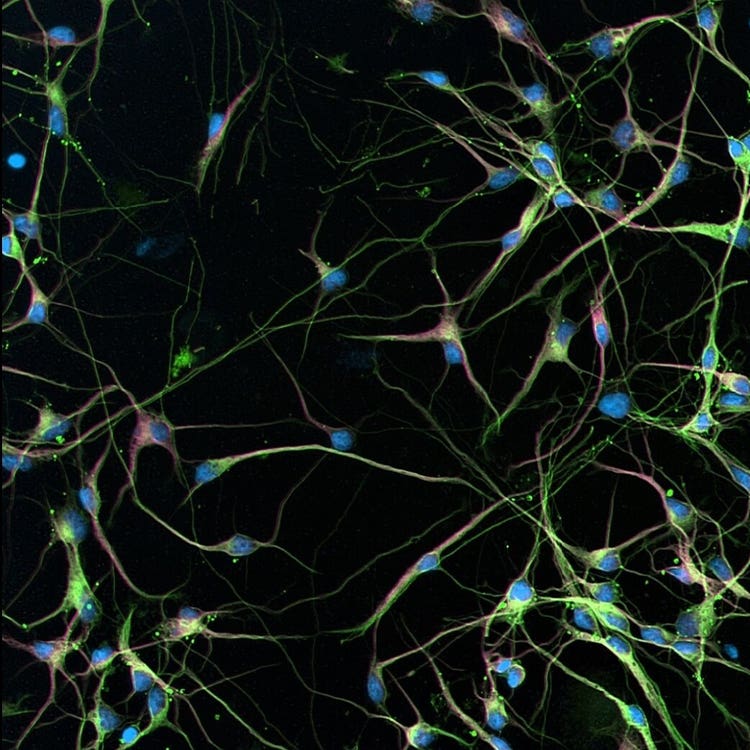

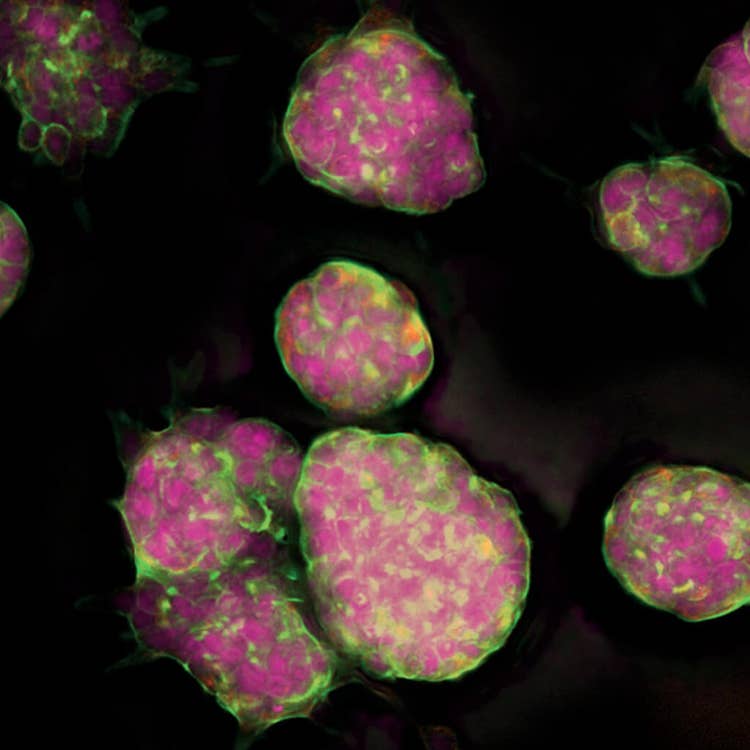

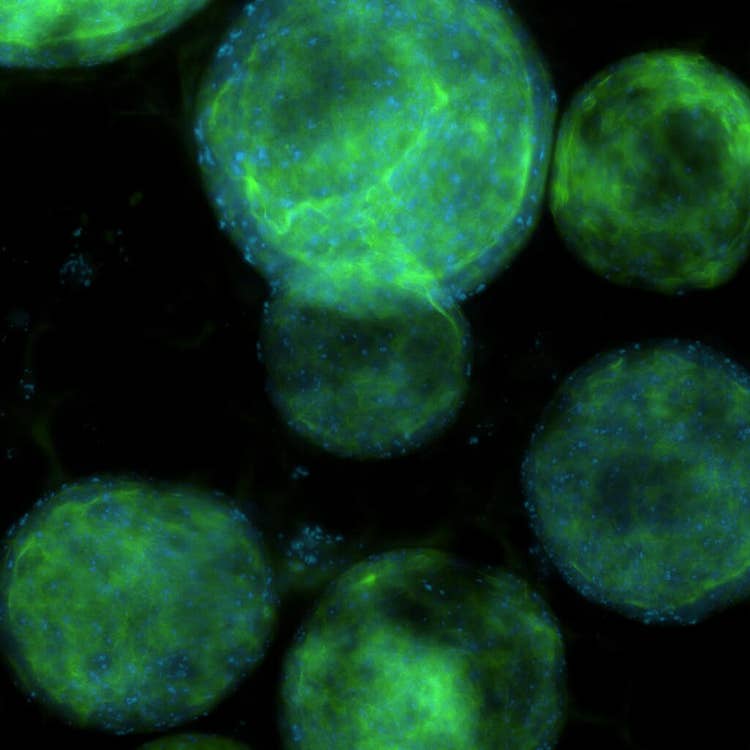

Hardware autofocus uses an LED beam to find reflective surfaces and is designed for speed. It works well for adherent samples in plates or chamber slides. When enabled, image-based autofocus searches a range for the best focus plane based on image contrast. It works well for slides with a coverslip or for samples in a plate that are not flat, such as suspension cells or spheroids. The ImageXpress Pico system with CellReporterXpress software provides reliable focusing across all of your labware to ensure high-quality imaging for a wide variety of sample types.

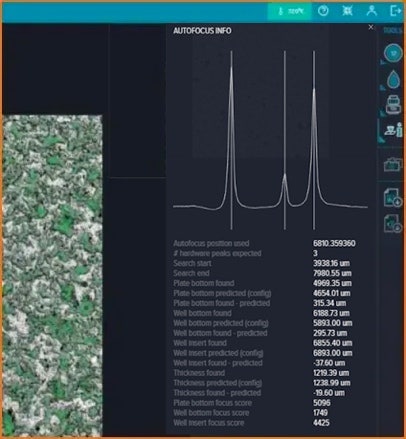

Detect surface algorithms

Plate Bottom

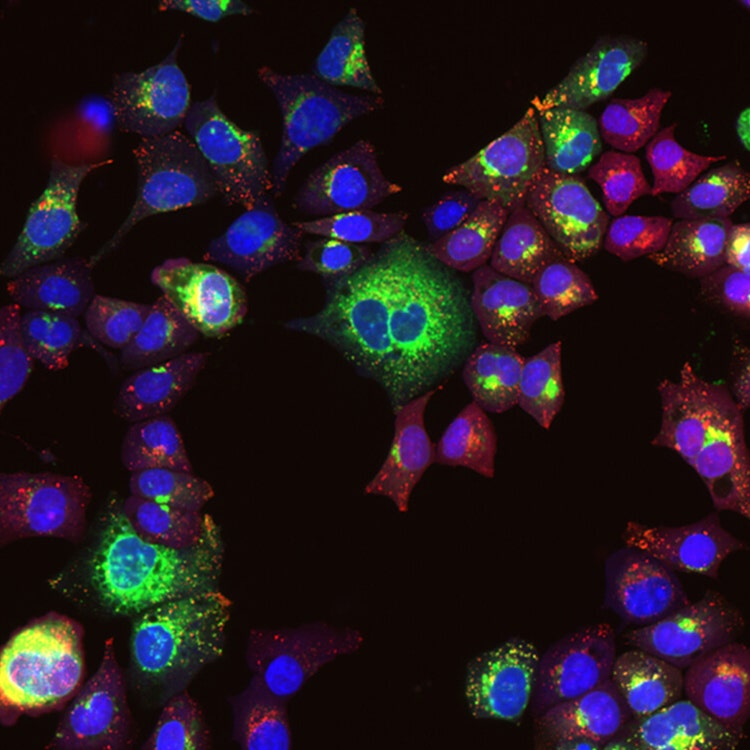

Hardware autofocus detects the surface closest to the objective—that is, the plate bottom. It works well for adherent samples in plates or chamber slides when imaging at low magnification or if your labware has a thick bottom. This is the fastest hardware autofocus option.

Well Bottom

Hardware autofocus detects the two surfaces closest to the objective—that is, the plate bottom and well bottom. The Well Bottom option is designed for samples in a liquid medium, such as well plates or chamber slides. This is the most commonly used hardware autofocus option.

Well Insert

Hardware autofocus detects the three surfaces closest to the objective—that is, the plate bottom, well bottom, and well insert. The Well Insert option is designed for well inserts in well plates or any labware design that has a distinct third surface.

Find best plane algorithms

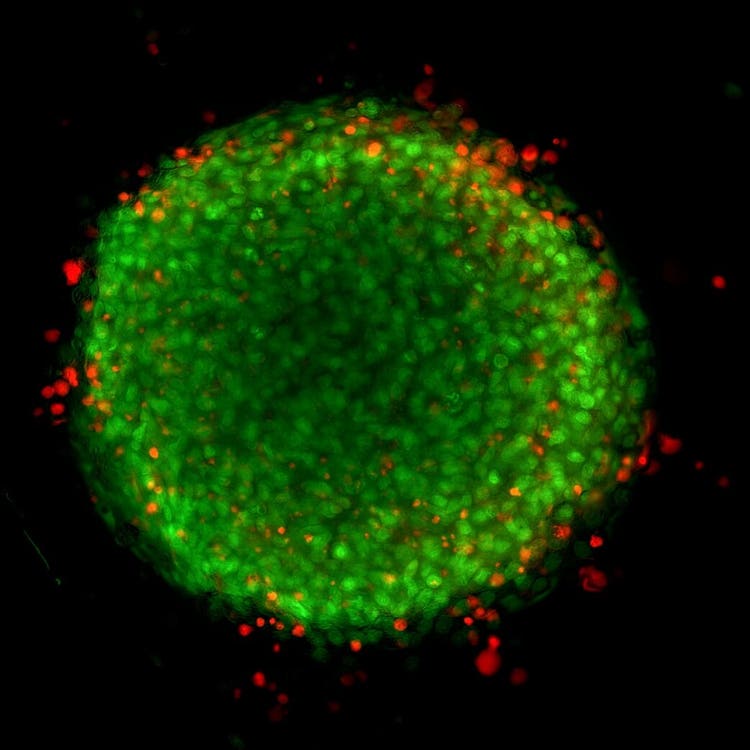

If the Detect Surface options do not provide satisfactory focus, select the Find Best Plane option to add image-based autofocus for the first channel within the selected search range. Adding image-based autofocus is useful for thicker samples, samples with variable best focus planes, or labware with variable thickness.

The Find Best Plane algorithms center on the surface detected by the hardware autofocus and search within a specific range to find the optimal focal plane.

- Normal Search Range – searches a range of 7.5% above and 7.5% below the labware bottom

- Wide Search Range – searches a range of 20% above and 20% below the labware bottom

- Superwide Search Range – Unlike these two options, which search around the surface, the Superwide Search Range searches a range of 300 μm above that surface.

Anchor focus position

For fastest screening speed, we have introduced the ability to select the Anchor Focus Position to save current focus position and disable the autofocus controls. The software uses the saved focus position for any ensuing snaps of preview images and for acquisition. This can dramatically speed the acquisition of plates at low magnification or when you are working with macroscopic samples like whole organisms or tissues.

Cellular image gallery