Clone Screening

Dedicated solutions for clone screening and single cell isolation

- Improved probability of finding rare clones of interest

- Objective selection of mammalian clones and microbial colonies

- Proven techniques for establishing monoclonality

Clone screening systems for monoclonality verification and colony picking

Our solutions for antibody discovery and cell line development provide dedicated, scalable, and easy-to-use products for establishing clonal populations. The systems feature a selection of options and models to address your specific research including multiple imaging modes, biology-specific pins, fluidics, and environmental control. These solutions combine intelligent imaging with analysis and automation to increase throughput, consistency, and provide image-based documentation.

Verify monoclonality easily

Objective selection, imaging, and data collection streamlines tracking of colony formation from a single cell.

Sort viable single cells efficiently

High accuracy robotics combined with gentle fluidics-based systems establish viable clones with much higher efficiency.

Streamline workflows

Automation with sample tracking increases throughput, allows for more walk-away time, and provides consistent results.

https://share.vidyard.com/watch/2dDXoDw8pL2dHFbYC2jdoQ

Introducing DispenCell Single-Cell Dispenser

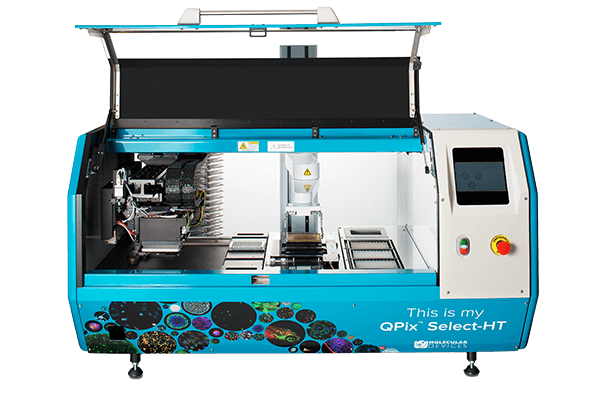

QPix 400 Series

Fully automate synthetic biology workflows for DNA assembly, antibody discovery and protein engineering

The QPix® 400 Series Microbial Colony Pickers combine intelligent image analysis with precise automation for fast and efficient screening of large libraries. With a variety of data tracking and assay tools, the QPix Software streamlines the control and management of complex and iterative processes.

- Automate several sample prep and plate handling processes such as transfer of bacterial liquid culture and plating on agar

- Streamline your workflow with scalable automation – pick up to 30,000 colonies per day

- Electronic data tracking for well-documented data control

- Sterile environment with customizable HEPA filtration options

ClonePix Series

Automate antibody discovery and cell line development workflows

Screen more clones with the ClonePix® Series in less time with monoclonal verification on day zero, then screen and pick for highest producers in weeks, not months.

- Screen 10X more clones than limiting dilution

- Increase probability of identifying high-value clones

- Condense the workflow into a single solution

- Eliminate or recover unstable clones early

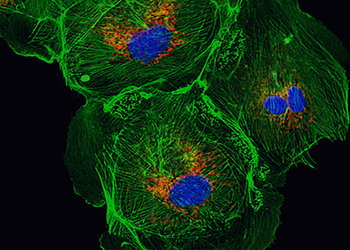

CloneSelect Imager and CloneSelect Imager FL

Verify monoclonality confidently

The all-new CloneSelect Imager FL adds high contrast multichannel fluorescent technology in addition to the standard white light imaging that allows for accurate single-cell detection and proof of monoclonality at day 0. Streamline your workflow with comparative confluence assays to identify and verify gene edits.

- Document evidence of single cells and confluency digitally for auditing and submission to regulatory authorities

- Image cells non invasively at multiple time points to monitor colony formation

- Screen using high resolution white light imaging

- Deliver real-time results with on-the-fly analysis

- Automation and integration ready

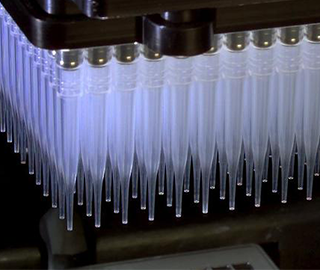

DispenCell™ Single-Cell Dispenser

A simple single-cell dispenser for proof of monoclonality

The DispenCell Single-Cell Dispenser is an automated laboratory instrument designed for fast, easy, and gentle single-cell isolation. Cell dispensing technology enables scientists to isolate single cell lines three times faster and at a lower cost compared to existing solutions.

- Easy, intuitive setup with no cleaning or calibration required

- Software that provides instantaneous proof of clonality and traceability post cell dispensing

- Unique technology gently handles the cell sample for better viability and cloning efficiency compared to manual pipetting

- Benchtop-size designed to fit under a hood, on a bench, or in a pre-existing automated workflow

- A patented disposable tip to ensure clean isolation of single cells and no cross-contamination, which is certified free from animal products and cytotoxic material

Inscripta enables scientists to perform digital genome editing with their Onyx system integrated in a fully automated workflow that includes the QPix system

The Fred Hutch Cancer Research Center uses the ClonePix 2 system to efficiently screen and isolate positive hybridoma clones

Harvard Medical School uses the QPix colony pickers to map networks of macromolecular interactions to help understand phenotype to gene relationship

Zymergen uses the QPix colony pickers to make better microbes in industrial fermentation

University of Edinburgh uses QPix colony pickers to scale up DNA manufacturing

Applications & Research

Find an extensive collection of application notes, research, and workflows related to clone screening including cell line development, antibody discovery, and more.

Cell Line Development

Stable cell lines are widely used in a number of important applications including biologics (e.g....

Antigen / Immunogen Discovery and Optimization

Vaccine development workflows vary widely depending upon the platform (e.g. inactivated virus vs. DNA vaccine)...

Antibody Discovery Using Phage Display

Phage display is a technique used to study the interaction of proteins displayed on the surface of a bacteriophage with other...

Hybridoma Workflow for Antibody Discovery

Hybridoma technology is a method for mass-producing antibodies in a hybrid cell line generated from the fusion...

Monoclonality

Monoclonality is term that describes a cell line that originates from a single progenitor (single cell) - and is therefore monoclonal. Cell line development and assurance of monoclonality are critical steps in the process of generating biopharmaceutical molecules, such as monoclonal antibodies.

Monoclonal Antibodies (mAbs)

Monoclonal antibodies (mAbs) originate from one unique parent cell, thus binding only to a single epitope. Monoclonal antibody discovery typically refers to the screening and identification of specific antibodies that target a specific epitope for the diagnosis and treatment of diseases, like the coronavirus for COVID-19.

Synthetic Biology

Synthetic biology is a broad term that refers to the manipulation of genetic pathways to harness the power of existing biological systems in novel ways (often to manufacture molecules or proteins). Synthetic biology applies principles that are derived from engineering, specifically design-build-test-learn cycles, to biological systems. By leveraging high-throughput workflows, synthetic biologists can accelerate this process.

Lab automation for high-throughput clone screening

Mammalian and microbial clone screening projects traditionally begin with a target—a receptor, protein, or gene that participates in a biological pathway of interest. Next comes screening, where thousands to millions of cells are tested and analyzed in relation to the target. This presents a significant bottleneck for labs as it requires laborious and time-consuming methods across a wide range of analytical platforms.

Gene Editing (CRISPR/Cas9)

Gene editing is a genetic manipulation in which a living organism’s genomic DNA is deleted, inserted, replaced, or modified. Gene editing is a site-specific targeting to create breaks in DNA through various techniques and does not always involve repair mechanisms.

Related Products & Services

View our complete line of clone screening systems along with an assortment of high-performance media and labware. We also offer services for instrument customizations and robotics.

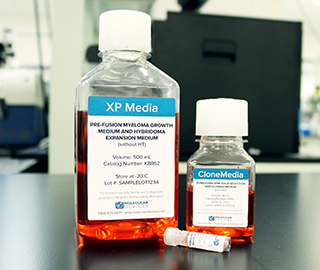

Media

An assortment of high-performance media. The use of CloneMedia ensures formation of discrete, clonal colonies with cell lines such as hybridoma, CHO, CHO-S, CHOK1 and others.

Consumables

Assortment of high-performance labware including cartridges, modules, filters and microplates to name a few.

Services

Customize your instruments, as well as automate entire workflow to meet the specific needs of your assay, method, or protocol

How can we help advance your next big discovery?

Our highly-qualified teams are on the frontlines with our customers, conducting remote or on-site product demonstrations, webinars, and more to help you solve your tough research challenges. How can we help you today?

I’d like to…